November 2, 2019

With the deadline on the project just around the corner, the need for full days on the weekends in at hand. There will likely be some vacation taken in the coming weeks, and the holidays certainly provide some additional work time. Today, my focus is on fairing the topsides. The owner decided on Alexseal's Flag Blue - an awesome choice for the topsides paint - and as such, I will need to ensure that the topsides surface is without blemish. The dark blue color shows even the slightest of issue on the boats surface.

I broke out the longboard...not to drop in on a perfect left, bottom turn with a long smooth arc into a hang ten, but to fair the surface of the topsides. The longboard would ensure that I bridge high and low spots over a length of roughly two feet, helping to fair the surface.

I started at the port bow, working the sprayed on guide coat.

The hand sanding with the longboard was a task requiring endurance, but ended up yielding great results.

I worked the surface in a crosshatch pattern - working top-forward to bottom aft, and then reversed that motion.

I turned at the transom and began my path to the starboard bow.

As I finished up the topsides fairing at the starboard bow, I moved onto the cove stripe. In a previous work session I applied fairing compound to cracks, voids, and shallow spots within the cove stripe, and now I'd hand sand to fair it out. I completed the starboard and port cove stripes.

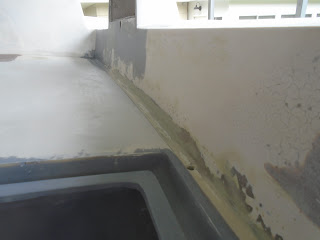

With the topsides finished, I moved back to the counter to sand the previous application of fairing compound. I sanded this with the Bosch and 80-grit pads.

I then moved up into the cockpit to sand the starboard molded fiberglass coaming, where it transitions to the gutter. This sanding was done by hand due to the tight radius between the gutter and coaming transition.

I used 60, 80, and 150-grit paper to work the surface fair.

I then moved onto the bridge deck to begin to fair in the core repair that I had recently undertook. I sanded this area with 80-grit discs and the Bosch 6" sander.

I vacuum up the sanding debris, wiped the surface with acetone, and applied a skim coat of the TotalBoat TotalFair fairing epoxy-based fairing compound. The bridge deck will require at least one more application of fairing compound.

While I was dialing in the "fairness" of surfaces, I applied another skim coat to the counter - the patched outboard well and new Torqeedo motor mount. I used West System epoxy and a combination of 406 colloidal silica and 407 low-density fairing compound.

Time to get all Norm Abrams! I love transitioning to working with wood, after spending so much time in fiberglass. I brought out the companionway hatch, having just applied a sealer coat of varnish, and used some 150-grit paper to rough up the surfaces across the hatch. Using compressed air, I blew off the sanding dust, and then wiped the surfaces down with a solvent.

The next step was to apply the teak decking caulk, so to that end I taped off the top of the hatch to protect against the caulk.

I applied the teak decking caulk to each of the grooves in the hatch top, and using a squeegee, I then pressed the caulk down to fully fill the groove.

I pulled the masking tape off the surface, and set the hatch out of harms way. I will wait for the caulk to sure before sanding the material flush with the hatch surface. Varnish on all three hatches will then begin!

As she sits today. Nearly ready for topsides primer, and subsequent application of deck and cockpit primer.

Total Time Today: 7.5 hrs

No comments:

Post a Comment